HIT-HY 270 Adhesive Anchor

Features &Benefits

Features

-Seismic ETA masonry approval, new TR053 and technical data available significantly increases your flexibility when designing steel-to-masonry connections.

-Simplify code-compliant design – design fastenings in masonry, including under seismic loads, with greater speed and ease using the PROFIS Engineering software suite.

-Compatible with HIT-SC composite sleeves for use in hollow base materials – offering greater flexibility through use of multiple sleeve combinations and also minimising mortar waste by allowing more accurate dosing.

-On-site anchor testing available – request Hilti’s on-site anchor testing service for verification of both tensile and shear loads in both horizontal and vertical directions.

Benefits

- Chemical injection fastening for the most common types of base materials.

- Hollow and solid clay bricks,calcium silicate bricks, normal and light weight concrete blocks.

- Two-component hybrid mortar.

- Versatile and convenient handling with HDE dispenser.

- Flexible setting depth and fastening thickness.

- Small edge distance and anchor spacing.

- Suitable for overhead fastenings.

- ETA approved for seismic loads in solid clay bricks (Rosso Vivo, Rosso Classico).

Brick Types and Properties

Instruction to this technical data

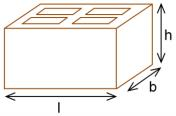

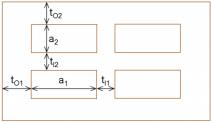

Identify/chooseyour brick (or brick type) and its geometrical/physical properties on the following tables.Information about edge and spacing criteria is available on page 5.

The pages reffered on the last column of the table below contain the design resistance loads for pull-out failure of the anchor, brick breakout failure and Mlocal brick failure for each respective brick. Notice that the data displayed on these tables is only valid for single anchors with distance to edge such that loading

capacity is not influenced by it – for other cases not covered, use PROFIS Engineering software, consult ETA-13/1036, ETA-19/0160, ETA-22/0395 or contact Hilti Engineering Team.

The resistance loads provided by this technical data manual are valid only for exact same masonry unit (hollow bricks) or for units made of the same base material with equal or higher size and compressive strength (solid bricks). For other cases, onsite tests must be performed-please consult page 18.

Generic Bricks

Bricks HC5, CC1 and CC2

Interior dimensions of the majority of the holes

Applications

-Fastening structural steel to hollow and solid masonry,

-Cost-effective seismic retrofitting and structural strengthening of old masonry walls

-Refurbishment and renovations of older masonry buildings,

-Heavy bracing of items such as sunshades on insulated materials,

-Fastening glass balustrade assemblies.

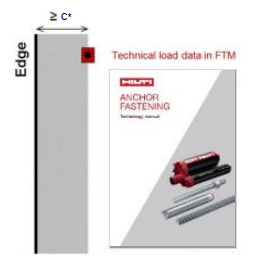

Allowed Anchor Positions

This FTM includes the load data for single anchors in masonry with a distance to edge equal to or greater than c* .

-c* is the distance from the anchor to the edge of the wall, such that the loading capacity of the anchor is not influenced by the edge.

-Minimum spacing between anchors = MAX (3 x hef ; size of brick in respective direction). This applies for a (conservative) manual design/calculation of a baseplate using the load tables in this manual.

-For an optimized design or cases not covered in this technical data, including anchor groups, please use PROFIS Engineering software or consult ETA-13/1036, ETA-19/0160, or ETA-22/0395.