FS-ONE MAX FIRESTOP INTUMESCENT SEALANT

Features &Advantages

Features

-For effectively sealing most common through penetrations in a variety of base materials – including concrete, masonry and plasterboard.

-For use in all types of pipe penetrations – metal pipes, insulated metal pipes and plastic pipes.

-For use in most types of cable penetrations – single cables, cable bundles, cable trays and mixed.

-Versatile – one product for most firestop applications 18-month shelf life.

Advantages

-One product for a variety of common through penetrations.

-Cost-effective,easy-to-use solution.

-Water-based and paintable.

-Industry-leadingVOCresults.

-Ethylene glycol-free.

Technical data

| Chemical basis | Water-based acrylic dispersion |

| Approx.Density | 84.3Ib/ft3 |

| Color | Red |

| Approx. cure time | 2mm/3days |

| Application temperature range | 35°F to 104° (1.5C to 40°C) |

| Temperature resistance range | -4°F to 212°F (-20°C to 100°C) |

| Storage Temperature | 35°F to 77F (1.5°C to 25°C) |

| Tackfree time | 20mins (@ 73°F / 50% rel. humidity) |

| Shelflife | 18 months |

| Mold and mildew performance | Class 0 (ASTM G21-13) |

| Mold and mildew resistant | Yes |

| Expansion ratio (unrestricted, up to) | 1:5 |

| Paintable | Yes |

| Chemlcalreslstance | Yes |

| Electricalresistance | Yes |

| FBC compatible (Lubrizol) | Yes |

| Intumescent | Yes |

| W-rating | Yes |

| M-rated | Yes |

| LEED vOC (input) | 9g/L |

| LEED V4 Compliant | Yes (CDPH v1.2-2017) |

| STC rating (ASTM E90) | 62 (relates to specific construction) |

| Movement | ±7.5% |

| Surface burning characteristics (ASTM E 84-14) |

Flame Spread: 0 Smoke Development: 10 |

| California State Fire Marshal approval | CSFM Listing 4485-1200:0108 for FS-ONE MAX Intumescent Firestop Sealant |

| Tested in accordance with | ASTMG21,ASTME90,CAN/ULC-S115, UL 1479, ASTM E 814 , ASTM E84 |

Applications

-For effectively sealing most common through penetrations in a variety of base

materials.

-For use on concrete,masonry and drywall.

-Mixed and multiple penetrations.

-Metal pipe penetrations: copper, steel and EMT.

-Insulated metal pipe penetrations: steel and copper.

-Plastic pipe penetrations:closed or vented.

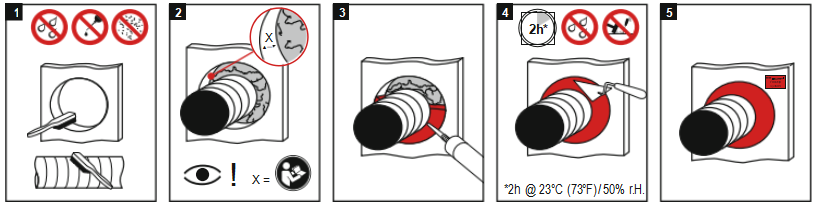

Setting Instructions

Storage

| Storage conditions | Keep cool. |

| Store in a dry place. | |

| Keep only in the original container in a cool, well | |

| ventilated place away from : Keep container closed when not in use | |

| Material used in packaging/containers | No additional information available |

| Incompatible products | Strong bases. Strong acids. |

| Incompatible materials | Sources of ignition. Direct sunlight. |

| Storage temperature | 5 – 2 5 ° C |